🇮🇳Voice#13: “Made in China” to “Made in India”: The Unintended Consequences of Apple’s Move to India

The human rights issues that get shoved under the rug

You may start seeing the following words on your beloved iPhones: “Designed by Apple in California. Assembled in India."

If you haven’t heard, Apple has started making the new iPhone 14s in India much earlier than anticipated.

But this transition isn’t necessarily new.

Apple has been transitioning its smartphone manufacturing base out of China since 2017. There are several reasons, but the two main ones are: 1) to reduce reliance on China and 2) to reduce labor costs.

The move has been widely reported as a positive one, which signifies a key milestone for India’s decisive move to becoming the world’s factory, despite the global recession.

And rightfully so.

Apple’s move is formidable from a geopolitical and economic standpoint.

Geopolitically, China has been a headache to most manufacturers due to authoritative zero-covid policies, rising labor wages, and unstable relationships with the U.S.

Economically, Apple is the most valuable company in the world, and the iPhone, its most valuable product, accounts for 50% of revenues. In absolute numbers, about $190~$200billion.

Considering that India only started to manufacture smartphones in 2014 (less than ten years ago), it is remarkable that they were able to woo the global smartphone titans. And the second and third economic effects of Apple’s decision are enormous.

“It’s a thoughtful move by the government aimed at wooing Apple to bring significant iPhone manufacturing to India, when the iPhone maker shifts, an entire economic ecosystem follows. The next five years will be dramatic, and India could become the new China in phone manufacturing.” — Hari Om Rai, Lava Founder

However, there is a caveat to the explosive growth that doesn’t get much spotlight in the news: human rights issues in new factories.

As India tries to hit aggressive growth targets, there have been multiple protests in iPhone factories with horrible working conditions.

If you own an iPhone or want to buy one, you may want to understand what is happening in Apple’s transition to India.

In this article, I will go over India’s aggressive goals, Apple’s ecosystem, and where the growth pains are showing.

India’s Transition to the World’s Manufacturing Hub

India’s economic growth is nothing short of impressive.

Aside from 2020 (COVID), it has enjoyed 5%+ GDP growth during the 2010s and is forecasted to grow at 6.5% for 2022–2023.

India is Asia’s third-largest economy and has overtaken the United Kingdom to become the 5th largest. Can you believe it?

From being part of the Commonwealth just 70 years ago, it is stunning to see India overtake the United Kingdom.

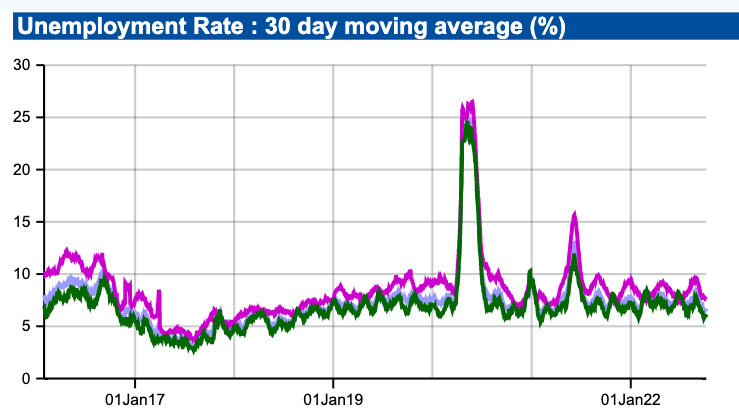

Despite such impressive economic growth, India has one massive problem: the unemployment rate. And it has been particularly affected by the pandemic.

Although measuring unemployment in a country like India is tricky, it runs to about ~6.5%. In comparison, China is about 4%.

Around 40% of the workers are still engaged in agriculture.

To create massive employment, Modi started the “Make in India” campaign in 2014. Furthermore, India began the Production Linked Incentive (PLI) scheme to accelerate growth, which provides incentives for key manufacturing sectors.

Mobile manufacturing was selected as one of the critical sectors for growth. And the incentives announced have been a massive boon for the growth spurt. One is an incentive of 4% to 6% on incremental sales of goods manufactured in India.

The results of the scheme have been a success so far.

India didn’t have a single mobile manufacturing factory in 2014. Now, India is the second largest mobile manufacturing factory in the world, just after China. India had been a large importer of mobiles from China, but now they are largely self-sufficient.

There have been 30 global and local players accepted to the production-linked scheme (Nokia, Rising Star, etc.)

Of these, three names stick out in particular: Foxconn, Pegatron, and Wistron, all of which are Apple’s main manufacturers from Taiwan.

Apple’s Transition to India

Apple started working with China in 2001 with the iPod. So Apple and China have been linked for close to two decades.

Over the two decades, China has built an ecosystem to handle the sourcing, handling, and assembling of complex parts for the iPhone. Apple purchases components from suppliers in 43 countries, sends them to China and assembles them.

By 2010, approximately 90% of Apple’s products are made in China.

Fun fact, you can go to your iPhone to see where it has been manufactured. Go to Settings > General > About>, and you can find the “Model Number.” The letters before the slash (1 or 2) are where your iPhone has been manufactured. “CH” is China, “J” is Japan, “TH” is Thailand, “VC” is Canada, etc.

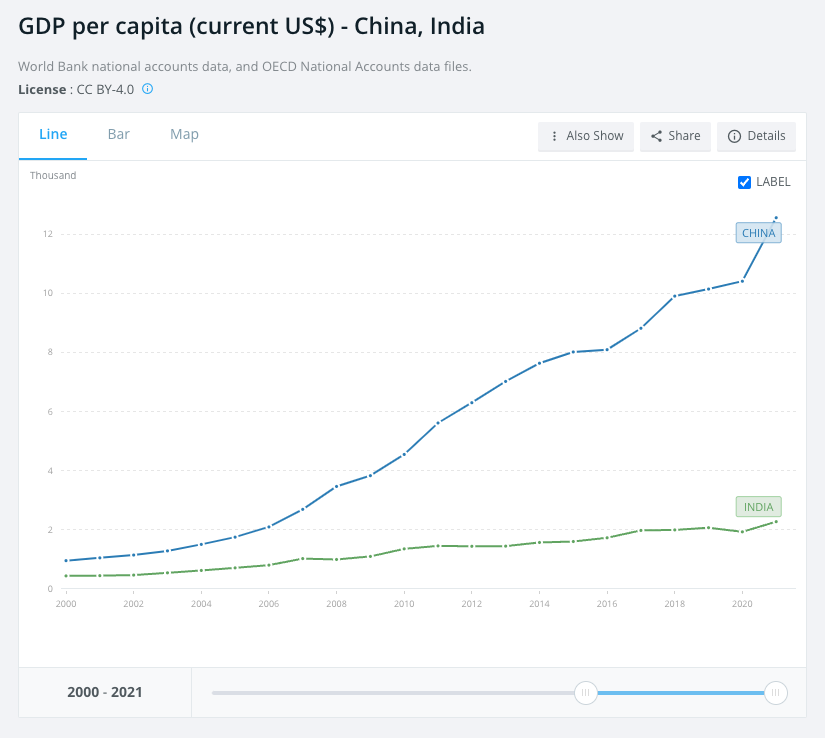

As China took a formidable position as the “world’s factory floor,” its GDP per capita skyrocketed during the last two decades.

While China and Apple have had a mutually beneficial relationship for nearly two decades, Apple has tried reducing its dependence. And although it may seem like the move has been triggered by China’s zero-covid policy and recent geopolitical tensions between US and China, the transition to India started in 2017.

At first, the main reason for the transition was the incentives from the Indian government to boost manufacturing.

The beginning was Wistron, one of Apple’s leading suppliers, setting up a subsidiary in 2017. They have built the iPhone SE (2017) and iPhone 6s (2018). After Wistron came Pegatron and Foxconn (the two other gains in Apple’s ecosystem) investing in India.

Then the pandemic and further geopolitical tensions accelerated Apple’s transition to India. Last year it was estimated that India produced 3.1% of the manufacturing supply of iPhones.

Morgan Stanley estimates the number to be 6~7% in 2022. And the trajectory seems to be strong.

The obvious advantages for Apple are the production-linked incentives from the Indian government and the cheap labor wages. It is estimated that India’s labor wages are 1/3 that of China's.

With an explosive trajectory, India is estimated to manufacture 25% of Apple’s iPhones by 2025.

But it is not all positive news.

There are growing pains when going through rapid expansion, with a major one being: the exploitation of workers.

In many factories, employees work long hours for little pay and are often denied fundamental rights such as freedom of association and collective bargaining.

This can result in extreme conditions, such as exposure to hazardous materials or dangerous equipment.

And Apple’s factories have not been an exception. Numerous incidents have happened but get less spotlight.

Unintended Consequences

On December 2020, Forbes wrote: Report: iPhone Factory In India Committed Multiple Labor Violations, Underpaid Wages.

Due to wage underpayment, irregular working hours, and poor working conditions, there was an outbreak of violent protests at a Wistron factory in India.

You can see a video capturing the incident here.

159 people were arrested as they broke down glasses and lights in the factory.

It has led to $7.7M in damages to the factory, which is substantial.

What was the reaction?

Local politicians and authorities were more concerned about the negative repercussions of the violent incident to possible foreign investments. State Minister Jagadish Shettar commented he will be putting “stringent measures to prevent such unpleasant events from recurring.”

Unfortunately, this wasn’t the only human rights incident.

Pegatron’s factory was also on probation one month before this incident due to students working night shifts and overtime.

Furthermore, in December, Foxconn’s factory was scrutinized last year as protests erupted after over 150 women were hospitalized from food poisoning.

Let’s paint a picture.

Barely 150 square feet of room.

Seven female workers crammed.

No bed, no mattresses.

Just one fan and one light.

No attached washroom or bathroom.

One window.

Wage is $120 (10,000 rupees)/month.

Unhygienic food that led to the hospitalization of nearly 150 people.

These are the conditions in the Foxconn factory that resulted in violent protests.

As the manufacturing capabilities in India are set to accelerate exponentially, we can expect similar incidents to happen.

Human rights incidents occurred in all three of Apple’s main suppliers in one year.

But who is to blame? Apple, with its aggressive growth targets and strategic move toward India? The Indian government prioritizing foreign investments with cheap labor costs?

There is one stark difference between China's and India’s governments. China has been a closed country for many years, with its government keeping a tight grip on information and limiting contact with the outside world.

On the other hand, all of the incidents in India are widely reported for the entire world to see. So will we see improvements? At what rate?

Until we know the answer to that question, we should ask, why are iPhone prices increasing?

Alternatively, you can get a Medium subscription for $5/month. If you use this link, it will support me.

Further Reading

India’s Top Conglomerate in Talks to Join Club of iPhone Makers

At 75, India seeks way forward in big but job-scarce economy

India second-largest phone manufacturer globally, shows govt …

Apple’s New iPhone 14 to Show India Closing Tech Gap With China

Apple iPhone Exports From India Doubling in Boon to Modi’s Plan

Modi’s Make in India revolution is coming at the cost of Indian factory workers

Protests at Indian iPhone plant offer a lesson for investors

Apple puts supplier Foxconn’s India plant on notice after protests

Interview: Arvind Subramanian, former Chief Economic Advisor to the Government of India

Report: iPhone Factory In India Committed Multiple Labor Violations, Underpaid Wages.

Apple Factory Violence | “PM Very Worried”: BS Yediyurappa On Violence At iPhone Factory

The future rise of India is an interesting topic. I wonder if the West would react adversarially to India, once India has reached a certain threshold, similar to its reaction to China. Time will tell. In the meantime, inflation has a hidden and curious result on toilet paper. https://quannguyen128.substack.com/p/inflation. I hope you would enjoy it.